ADS EVO

Automatic Driving System

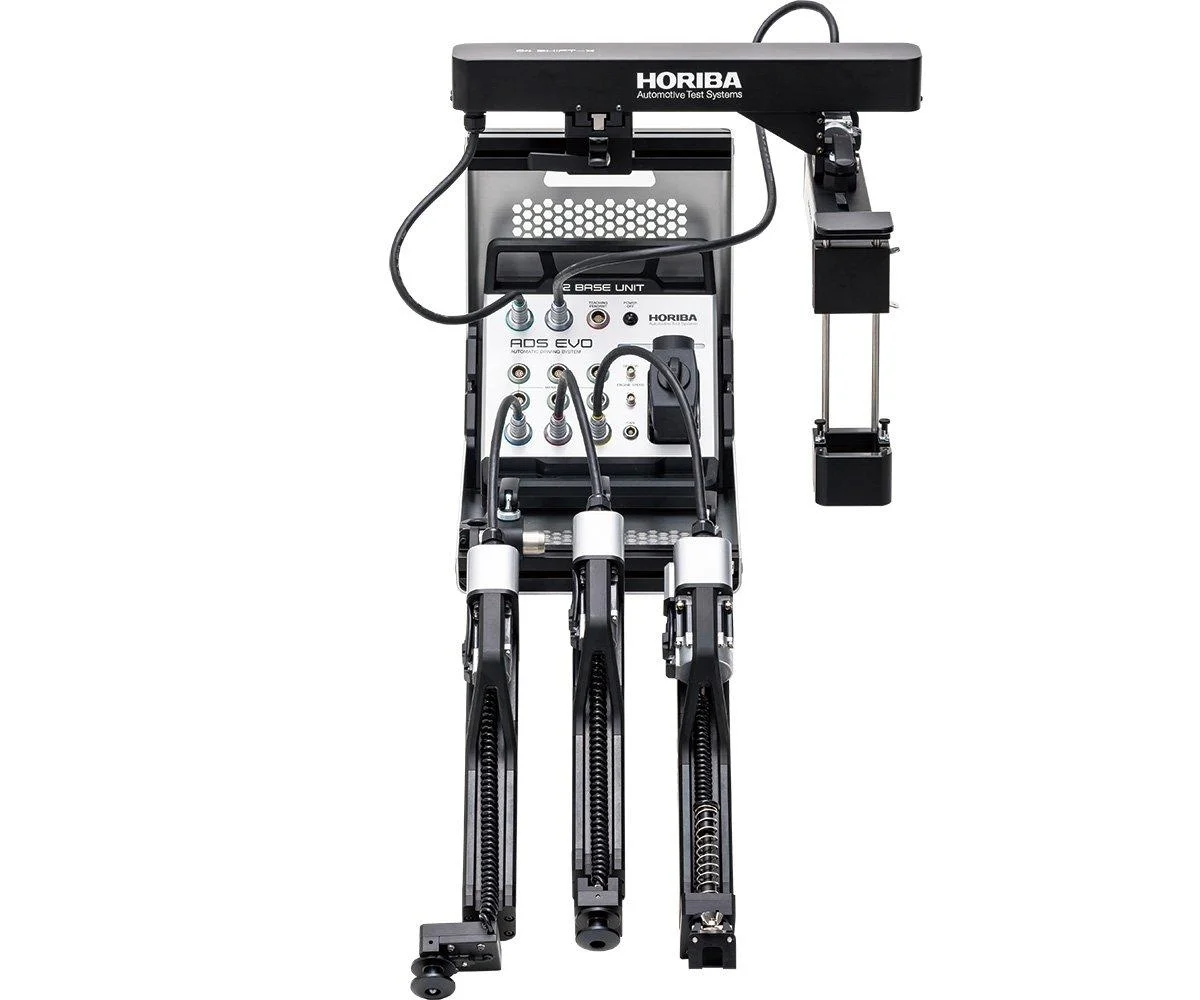

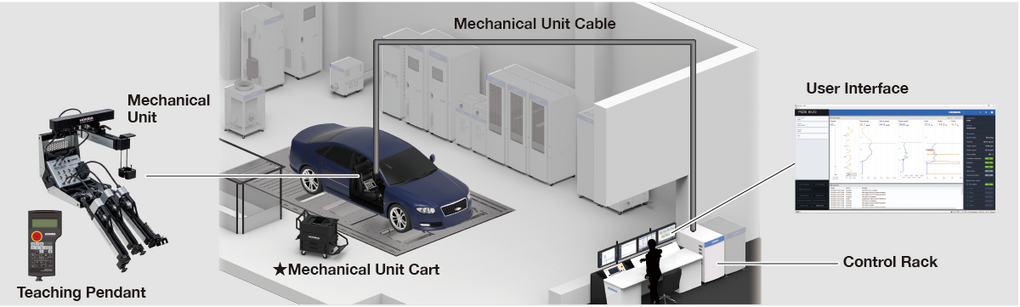

The ADS EVO is an automated driving system for chassis dynamometer test cells, enabling vehicle developers to reduce development times and ensure accurate, repeatable global test cycles. Lightweight and easy to install with ISOFIX standards, it supports a wide variety of vehicles and environmental conditions, improving test efficiency and consistency.

Why Choose ADS EVO

- Automated driver for consistent test cycles

- ISOFIX installation for reduced setup time

- Ergonomic, self‑contained mechanical unit

- Compatible with MT, AT, CVT & Hybrid/EV

- Operating range −40 °C to 80 °C

- Intuitive design for streamlined workflows

Key Advantages of ADS EVO

Automates driver

Ensures consistent global test cycle accuracy

Quick installation

Reduces setup time significantly

Wide temperature range

Reliable under extreme conditions

MT, AT, CVT & Hybrid/EV

Supports diverse drivetrains

Applications of ADS EVO

Emission Testing

Automates global chassis dynamometer cycles for accurate, repeatable measurement of tailpipe emissions under real‑world and regulated test protocols.

Electric Vehicle Development

Provides precise, programmable control of drivetrain inputs for RDE and lab‑based EV performance testing, reducing variability and shortening development timelines.

System Validation

Enables end‑to‑end validation of transmission, hybrid and autonomous control systems across MT, AT, CVT and EV platforms with consistent, reproducible driving profiles.

Technical Specifications of ADS EVO

Basic Functions

| Driving Functions | Standard drive traces (emissions, etc) ★Performance test mode Auto/Manual adjust (pedal and shift) Learning mode Warm up mode Constant speed mode Manual mode |

|---|---|

| Applicable Vehicles | MT, AT, CVT, ★Hybrid/EV Floor shift, ★Instrument panel shift, ★Column shift For both left and right hand drive vehicles |

| Other Functions | Measurement function:Dynamometer speed, Engine speed External operation input : Drive start/stop External condition input : Dynamometer ready/error,Blower ON External operation output : Synchronization signal with data processing device ★HOST communication:AK compliant |

Specifications

| Mechanical Unit | |

|---|---|

| Total Mass | Standard Specification : 30 kg |

| Unit Mass | 3 - 7 kg |

| Operating Environment | Standard Specification: -10 - 45℃ 30 - 90%RH(no condensation) ★Environment Resistance Specification : -40 - 80℃ 30 - 90%RH(no condensation) |

| Actuators | Accelerator:Stroke length 150 mm, Rated output 160 N, Maximum operating speed 0.61 m/s Brake:Stroke length 200 mm, Rated output 241 N, Maximum operating speed 0.61 m/s Clutch:Stroke length 200 mm, Rated output 322 N, Maximum operating speed 0.78 m/s Shift(X):Stroke length 190 mm, Rated output 193 N, Maximum operating speed 0.77 m/s Shift(Y):Stroke length 240 mm, Rated output 193 N, Maximum operating speed 0.77m/s Starter(PUSH):Rated output 16 N ★Starter(TURN):Rated output 0.97 N・m ★Up to 5ch push actuators can be added |

| Control Rack | |

|---|---|

| Size | 578(W) × 929(D) × 1000(H) mm |

| Operating Environment | 5 - 40℃ 20 - 80%RH(no condensation) |

| Power supply | Single phase:AC 200 - 240 V ± 10% (Max 250 V) 50/60 Hz 3.0 kVA or Single phase:AC 100 - 120 V ± 10% 50/60 Hz 3.0 kVA |

| Others | Teaching pendant:Used for learning shift positions and other various settings Mechanical unit cable:Connect mechanical unit and control rack |

★: Option

Related Products

NOT SURE WHAT YOU ARE LOOKING FOR?

BOOK A CONSULTATION

Our experts are here to guide you to the right solution. Fill out the form and we'll get in touch shortly.